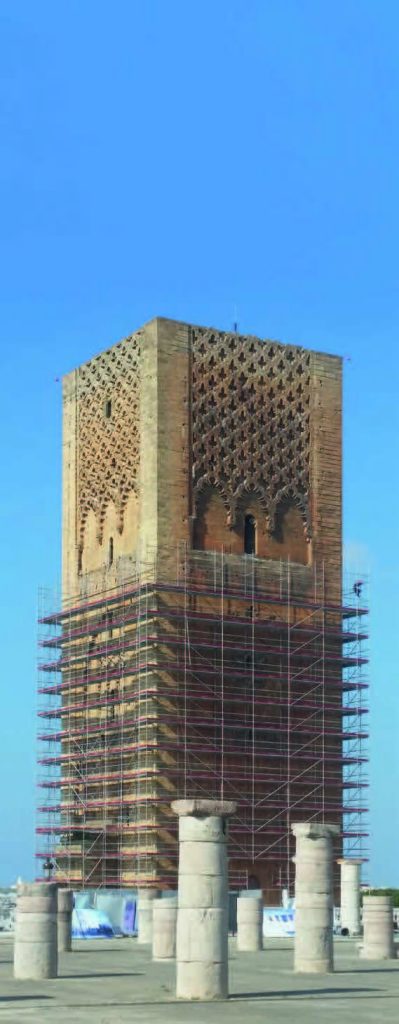

Hassan Tower scaffolding: an exceptional project, a technical challenge

An emblematic monument in the city of Rabat, the Hassan Tower has been undergoing a vast restoration project since the beginning of the year, a first since its construction in the 12th century. Because of its scale, novelty and visibility, this particularly prestigious project must be exemplary.

Layher was entrusted with the supply and erection of scaffolding equipment, as well as a freight elevator. This was an opportunity for its teams to demonstrate their ability to meet numerous technical challenges, thanks to :

- The nature of the work to be carried out: the restoration requires, among other things, the removal of stones weighing several hundred kilos from the scaffolding;

- The height of the monument: the tower exceeds 50 metres at its highest point;

- Wind exposure: built on a hill facing the ocean, the Hassan Tower is subject to winds that can exceed 100 km/h.

- The impossibility of settling on the Tower, which has been a Unesco World Heritage Site since 1995.

The need for an adapted response: modern equipment, recognized expertise

Faced with these constraints, Layher designed a German-made Universal scaffolding structure. Equipped with an 8-way rosette system every 50 centimetres, this prefabricated “multidirectional” scaffolding is characterized by its adaptability. It can be installed on any type of building, regardless of its shape (cylindrical, irregular, etc.). And with a “keyed” fastening system requiring only a single hammer blow, assembly is particularly quick. The Hassan Tower, for example, was entirely covered in scaffolding in the space of a month by a team of just ten people.

In addition, it was necessary to ensure that the equipment was properly installed under the conditions described above. With this in mind, Layher drew on the skills of the engineers in its design office, who drew on their experience on sites as important as the Eiffel Tower and the Turin Olympic Games to redouble their ingenuity and make the renovation of the Hassan Tower possible. In particular, they used exceptional methods such as fixing the structure by compression (known as “butonnage”), constructing part of the scaffolding without ground support (known as “cantilever”) or adding ad-hoc reinforcements.

A constant concern: worker safety

Faced with the high number of accidents linked to working at height, Layher has made worker protection a priority.

This takes two forms:

- The importance we attach to the quality of our products: systematic checks are carried out at every stage of the production chain, and our products are certified by independent international bodies.

- Support for assembly partners and end-users: Layher attaches particular importance to consulting and training its customers, to ensure that they comply with the most stringent international safety standards. For the Hassan Tower, the professionally erected scaffolding was fully equipped with guardrails (rails, subrails and plinths) on the outside, and the space between it and the wall was reduced to a minimum.